Technical Performances

Time saving and increased yield

Benefit from a higher productivity and an autonomous working thanks to the automated injection system and the automatic peak's end detection.

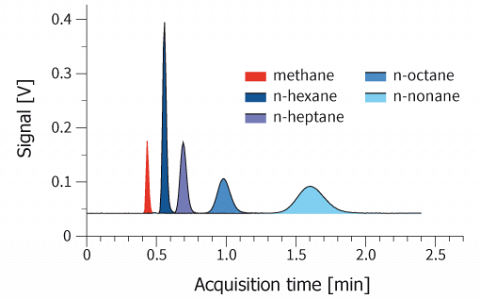

The above example shows that twenty minutes are sufficient to get the retention times of a homologous series of n-alkanes and then the resultant dispersive component of the surface energy. Indeed, the device is able to stop the analysis once the first probe has been fully detected and inject the next one without any human intervention. This allows the operator to handle other tasks within this automatic cycle.

Continuous and mastered injection

Take advantage of a unique injection method allowing a one-step analysis.

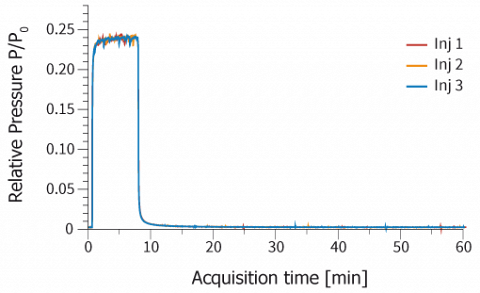

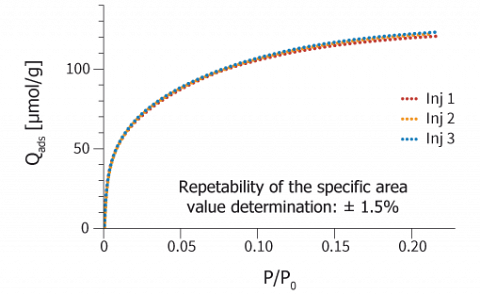

The automated injection system provides a continuous and controlled flow of probe molecules thus avoiding successive injections. In this example, 60 minutes are sufficient to get several hundred experimental points. Moreover, this innovative method leads to a repeatability level which was not achievable before.

Guaranteed repeatability

The reliability of the measurements has been proved through several repeatability studies such as the two examples below:

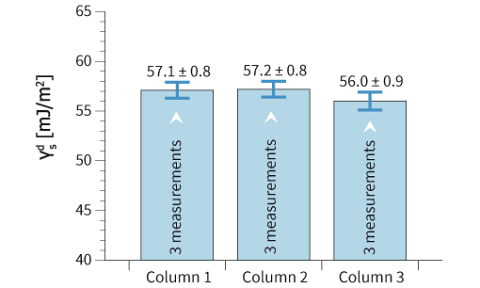

For the surface energy:

When computing the dispersive component of the surface energy through the Infinite Dilution method, in 3 different columns and with 3 replicas each time, an average standard deviation of less than 1.5 % is observed.